Our range of technical product and services are constructed in compliance to industry standards. We ensure that the range of product and services on offer has passed through stringent quality testing and provide seamless operation.

We provide valve maintenance services, rotating equipment services and hydraulic bolt torque services.

Testing & CalibrationTo verify and re-setting of opening pressure. Our Company standard practice is complying with manufacturer standard practice and API Standard 527.

Service and LappingAPI RP 520 and API RP 521 CertificationProduce testing and calibration certificate. List of Equipment used for servicing

Range Of PSV Brand/ Maker We ServiceDresser Consolidated, Farris Engineering, Anderson Greenwood Crosby, Birket, Motoyama Crosby, Fukui, Tai Milano, Broady, Lesser, Kunkle, Conbraco, Bopp Reuther, Swagelok/Nupro, Triangle Control/Sempell & Nakakita.

|

|

|

Control valve is a device to control and keep prrocess variable such as pressure, flow, level and temperature within a required operating range to ensure the quality of the end product.

Control valve is a device to control and keep prrocess variable such as pressure, flow, level and temperature within a required operating range to ensure the quality of the end product.

Testing & Calibration

To conduct stroking, seat leakage and shell/ body test. Company standard practice is complying with manufacturer standard practice and API Standard FCI 70-2.

Service, reconditioning/polishing of cage and trim Service and reconditioning/polishing of Control Valves cage and trim.

Company standard practice is complying with manufacturer standard practice.

Certification

Produce testing and calibration certificate.

Equipment used for servicing

Test Clamp, Test Control Panel, Hard Communicator, Power and Hand Tools.

Range Of Control Valves Brand/ Maker We Service

Fisher, Flowserve, Severn Glocon, Yamatake and Samson.

Testing & Calibration

To conduct functioning/stroking, seat leakage, backseat and shell/body test. Company standard practice is complying with manufacturer standard practice and API Standard 598.

Service and Reconditioning.

To clean valves internal parts, reconditioning/polishing of valves cage and trim. Company standard practice is complying with manufacturer standard practice, API Standard 598, API Standard 600 & API Standard 602.

Certification

Produce testing and calibration certificate.

Equipment used for servicing

Hydrostatic booster pump, pressure chart decoder, blind flange, multi-meter or hard communicator, high pressure hose, test pressure gauge and fittings.

Range Of Control Valves Brand/ Maker Serviced

Experienced in service valves brand such as Petrovalves, KVC, Kitz, Pibiviesse, Hartman, Tyco Flow, Hawa, RBR, Alfa, VIza, Mariani, Dafram, Whitey, Woodward.

Online valve greasing is fast and economic solution for hard to operate, jammed/stuck and passing valve. It will reduce downtime, easy to operate and in safe manner and extend lifespan of valves.

Valve Flushing

Inject valve flushing liquid to clean and remove all harden grease, sludge and any others substance.

Valve Lubricant

Inject synthetic lubricant to protect and lubricate internal parts of valve. Valve Sealant

Valve Sealant

Inject synthetic valve sealant to seal valve at close position. List of Equipment

Valve Master Pump, Junior Pump and Valve Flush Pump.

List of Consumables

Valve Flush, Valve Lubricant, Valve Super Sealant, Valve Master Sealant and Valve Repair Sealant.

Type of Valve

Our services cover Actuated/ Manual Ball Valve, Wellhead Gate Valve and Plug Valve.

Vibration and Noise Monitoring

Rotating machine has its own vibration and noise as result of bearing, shaft and gear. Online vibration monitoring can detect problem caused by bearing damage, shaft imbalance and other parts problem.

Installation & Commissioning

Check plate and ensure it surface is level. Pump and motor must be installed and aligned (dial or laser) for smooth pump running without produce vibration and noise.

Servicing

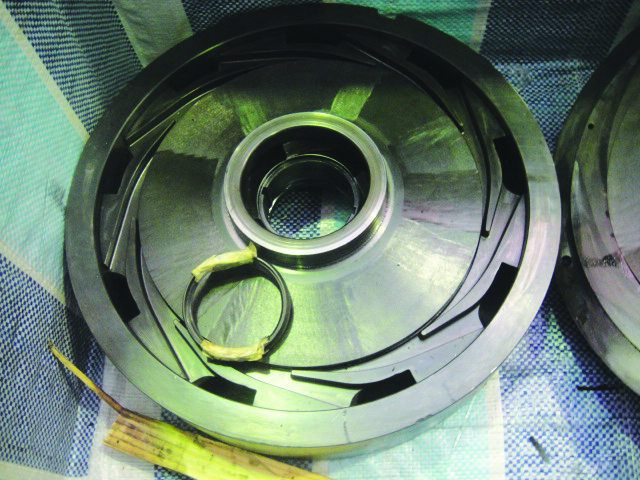

Strip down pump and examine all parts condition. Check parts tolerance and compare with manufacturer tolerance range. Clean all parts and replace wound or damaged parts with OEM parts. Company standard practice is complying with manufacturer standard practice.

Type of Pump/ Compressor

Centrifugal (Axial Flow), Positive Displacement (Rotary, Piston/Plunger & Screw).

Using hydraulic torque wrench will improve joint sealing and prevent joint leaking during operation.

We provide rental of hydraulic torque wrench and onsite hydraulic torque service.

We provide project supervision for your onsite employees or we can send our skill personnel together with equipment to perform hydraulic torque service.

|

|

|